Sandblasting Near Me Can Be Fun For Everyone

Wiki Article

How Sandblasting Near Me can Save You Time, Stress, and Money.

Table of ContentsHow Sandblasting Near Me can Save You Time, Stress, and Money.Sandblasting Near Me Things To Know Before You BuyThe 2-Minute Rule for Sandblasting Near MeSandblasting Near Me Things To Know Before You BuyThe Best Guide To Sandblasting Near MeThe Best Guide To Sandblasting Near MeThe 9-Minute Rule for Sandblasting Near MeThe Basic Principles Of Sandblasting Near Me

Sandblasting devices typically consists of a chamber in which sand and air are blended. The blend takes a trip via a hand-held nozzle to direct the particles toward the surface or job item. Nozzles come in a variety of forms, dimensions, and materials.Damp unpleasant blowing up [modify] Damp unpleasant blowing up usages water as the liquid relocating the abrasives. The advantages are that the water traps the dirt generated, and also oils the surface area. The water supports the influence on the surface area, reducing the removal of audio product. Among the initial leaders of the damp rough process was Norman Ashworth who discovered the advantages of using a wet process as a solid choice to completely dry blowing up.

The smart Trick of Sandblasting Near Me That Nobody is Talking About

A variant of damp blowing up is vapor blasting (or vapour blasting; U.K.). In this process pressurized air is added to the water in the nozzle generating a high speed mist, called "vapor". This procedure is also milder than wet blowing up, permitting mating surfaces to be cleaned up while keeping their ability to mate.

The Best Guide To Sandblasting Near Me

Mixing bits with water substantially lowers dust. Bead blasting is the procedure of removing surface area deposits by applying great glass grains at a high pressure without damaging the surface area. It is used to clean calcium down payments from swimming pool ceramic tiles or any kind of other surfaces, eliminate ingrained fungus, as well as lighten up grout color.In removing paint for car body work, bead blasting is liked over sand blasting, as sand blowing up has a tendency to develop a better surface area account than grain blasting. Bead blasting is commonly made use of in developing a consistent surface area coating on machined components.

The Best Guide To Sandblasting Near Me

The initial blast wheel was patented by Wheelabrator in 1932. Hydro blowing up this hyperlink is not a form of unpleasant blasting as no unpleasant media is utilized. Hydro-blasting, commonly understood as water blasting, is commonly made use of because it generally needs just one operator.This approach is optimal for cleaning interior and outside surfaces since the driver is typically able to send the stream of water right into places that are hard to reach making use of other techniques. Another benefit of hydro-blasting is the capacity to recapture as well as recycle the water, reducing waste as well as mitigating ecological impact.

3 Easy Facts About Sandblasting Near Me Shown

Greater stress are often required. The most common micro-abrasive blasting systems are industrial bench-mounted systems containing a power supply as well as mixer, exhaust hood, nozzle, and also gas supply. The nozzle can be hand-held or component placed for automatic operation. Either the nozzle or component can be relocated automatic operation.

10 Simple Techniques For Sandblasting Near Me

Wet blowing up is typically used in applications where the marginal dust generation is preferred. Mobile applications may or may not recycle the unpleasant.

7 Easy Facts About Sandblasting Near Me Shown

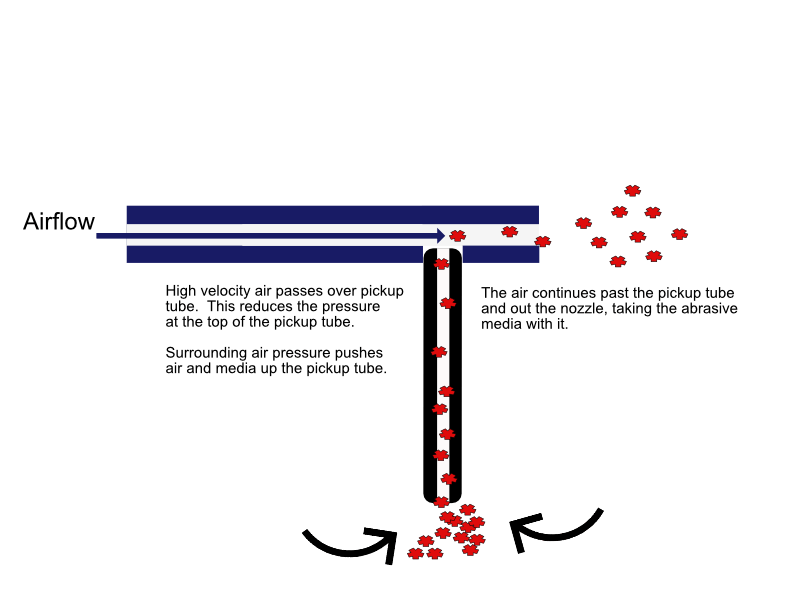

It usually contains 4 components; the containment (cupboard), the rough blowing up system, the abrasive recycling system and the dust collection. The driver blasts the components from the beyond the cabinet by placing his arms in gloves affixed to handwear cover holes on the cabinet, seeing the part with a view window, turning the blast on as well as off utilizing a foot pedal or treadle.There are three systems commonly used in a blast cabinet. Two, siphon and pressure, are dry and one is damp: A siphon blast system (suction blast system) makes use of the pressed air to develop vacuum cleaner in a chamber (called the blast weapon). The unfavorable pressure pulls abrasive into the blast weapon where the pressed air guides the abrasive via a blast nozzle.

7 Simple Techniques For Sandblasting Near Me

Nozzles come in a selection of forms, sizes, and also products. Tungsten carbide is the liner product frequently made use of for mineral abrasives. Silicon carbide as well as boron carbide nozzles are much more put on immune and also are commonly utilized with more difficult abrasives such as aluminium oxide. Inexpensive unpleasant blasting systems and also smaller closets utilize ceramic nozzles.The vessel is pressurized to the same stress as the blast hose connected to all-time low of the pressure vessel. The unpleasant is metered into the blast hose pipe and also conveyed by the compressed gas via the blast nozzle. Wet blast cupboards use a system that injects the abrasive/liquid slurry right into a pressed gas stream.

Report this wiki page